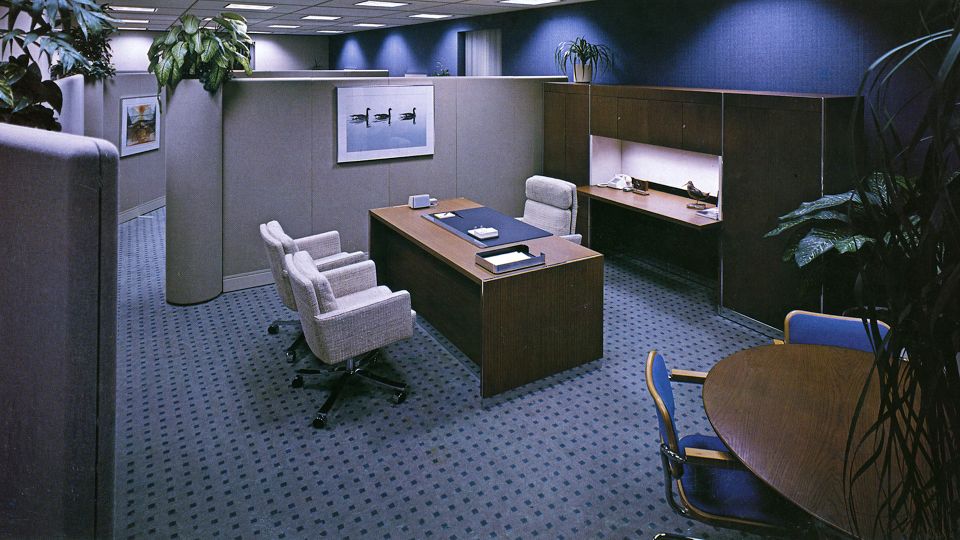

Carpet Tile

Collections

Resilient

Collections

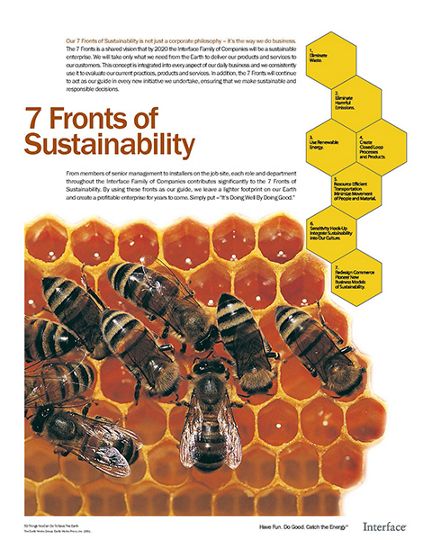

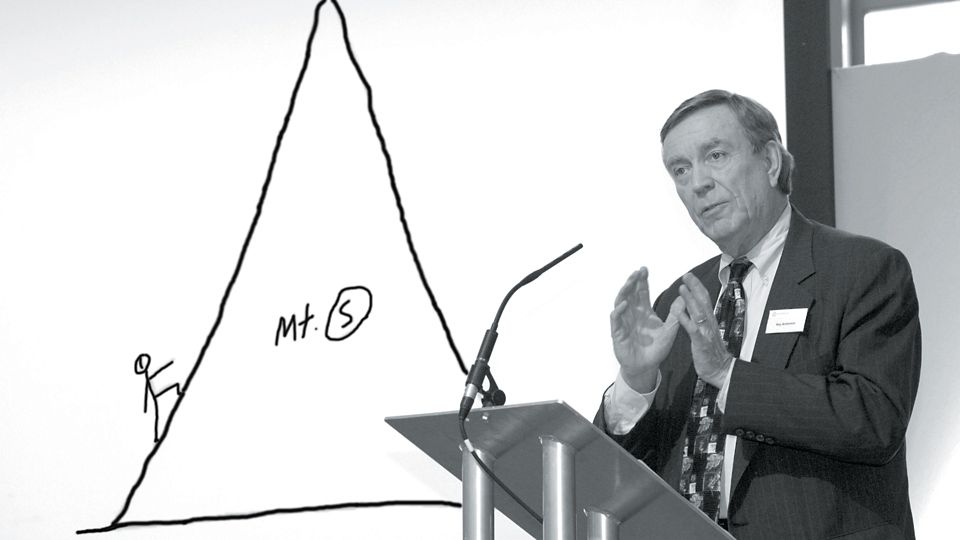

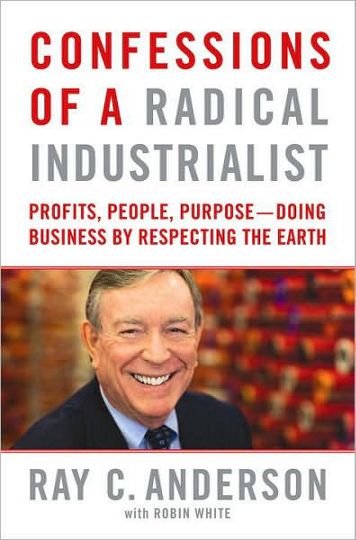

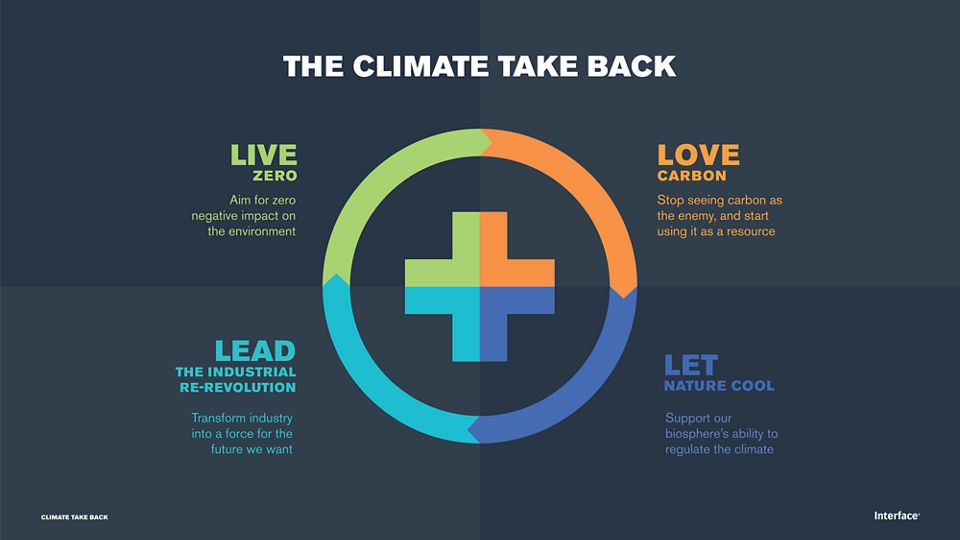

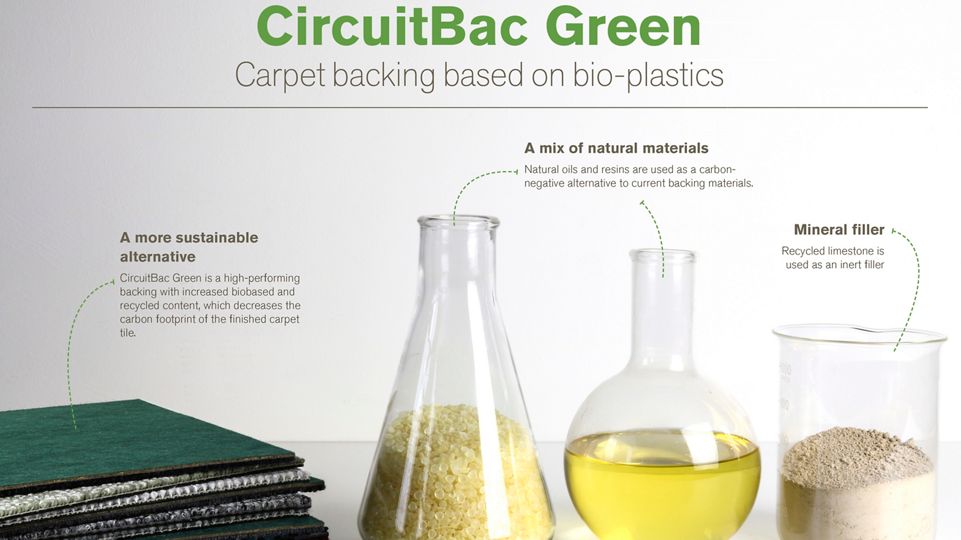

Sustainability

Design

Segments

More from Interface

More Links

Global Services

It’s flooring—and then some. Made for More.